Ball Mill Batch Ball Mill Manufacturer from medabad

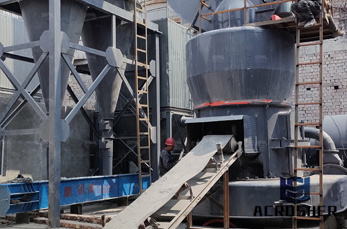

Ball Mill. We are a leading Manufacturer of batch ball mill, rod ball mill, iron ore grinding ball mill, ball mill, ceramic batch ball mill and ball mill for dolomite from medabad, India.

WhatsApp)

WhatsApp)

Ball Mill. We are a leading Manufacturer of batch ball mill, rod ball mill, iron ore grinding ball mill, ball mill, ceramic batch ball mill and ball mill for dolomite from medabad, India.

Ball mill with Central Drive Mill length Mil l diame te r M il l di amet er 5 3 2 3 2 1 3 5 6 6 4 4 Ball mill with Sid e Driv 1 Inlet 2 Outlet casing 3 Slide shoe bearing 4 Main gearbox 5 Mill motor 6 Auxiliary drive 1 3 Ball mill for cement grinding 3 Cement grinding taking on the tough tasks Cement ball mills have to achieve the desired

Ball mill in the cement grinding unit enith provide high performance cement grinding unit consumption results in lower operating costs per unit of production cement ball millset pricehree cement q2 net profit up 19 to rs292 price. Process Of Cement Grinding Unit Project Report.

Apr 13, 2015#0183;#32;Backed by an industry experience of 17 years, we have emerged as one of the eminent manufacturers of vertical Shaft amp; Rotary Kiln, Ball Mills, Steel Ball Mil...

Jun 01, 2018#0183;#32;During the grinding process, coarser material (size class 1) break to finer material (size class 2) and (size class 3) which are termed the daughter products, as shown in Fig. chemical reaction on the other hand can consist of say reactant A forming intermediate product B then proceeding to final product C or a competing reactant A to final product D can also

The difference between vertical roller mill and ball mill The ball mill is generally composed of a horizontal cylinder, a hollow shaft for feeding and discharging, and a grinding head. The cylinder body is provided with an abrasive body, the cylinder body is made of steel plate, and the steel lining plate is fixed with the cylinder body, and the grinding body is generally a steel ball, and

10/2/2016#0183;#32;Reliability amp; Product quality good partcicle size distribution in ball mill as we can play wtth Grinding media filling. VRM has less flexibility in controlling particle size distribution. Overall ball miil is good option for Cement mill but only has limitations for higher capacity, as two ball mill to be installed for One VRM, but in case of breakdown one ball mill can be in operation.

Feb 10, 2016#0183;#32;VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 TPH) and before implementing the project, we would like to

Vertical roller mills Vs ball mills has long been a raging debate in the cement industry. In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to design new grinding plants or a new integrated

A cement ball mill is a grinder that grinds the clinker methods for modeling the ball mill grinding and its the product Blaine, the unit of which is cm#194;#178;/g.. [1] et al, Advances

cement grinding unit ball mill from china . Second Hand Concrete Batching Plants For Sale In Malaysia. Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen. Raw Complex Gold Ore Processing Machine.

Ball Mill For Grinding Cement Unit Pakis Ball mill is the key equipment for grinding after the crushing process which is widely used in the manufacture industries such as cement silicate new building material refractory material fertilizer ferrous metal nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all

Cement Grinding Cement Plant Optimization . Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080 of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity mills.

Ball Mill For Grinding Cement Unitball Mill. MORE DETAILS: Cement Ball Mill. Cement plant clinker grinding unit capacity 21155 th motor power kw fineness cmg overview the ball mill for clinker is an efficient tool for fine powder grinding it is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric power

A Ball mill is a horizontal cylinder partly filled with steel balls (or occasionally other shapes) that rotates on its axis, imparting a tumbling and cascading action to the balls. Material fed through the mill is crushed by impact and ground by attrition between the balls. The grinding media are usually made of highchromium smaller grades are occasionally cylindrical (quot;pebs

Buy ball unit for grinding in the ball mill in the cement advancements in the ball mill in the cement grinding unit the cement clinker grinding circuit reduces the feed from 80 passing size between 10 and 20 mm to 100 passing 90 m the size reduction takes place in a two

18/7/2016#0183;#32;Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %. It is somewhat surprising that the number of different grinding processes and mill types used by the

Apr 20, 2020#0183;#32;The whole system of cement clinker grinding unit mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading. And the system is composed of cement mill, OSEPA highefficiency separator, elevator, packing machine and so on. In order to meet the customers'' requirements on different granularity of auxiliary materials, it can be equipped with high

The contract includes a 5200 Kws ball mill, fully engineered by Cemengal, and peripheral equipment and a Magotteaux XP4i130 fourthgeneration classifier for highstrength cement. The scope of the project includes full engineering and complete supply of mechanical, process, electrical and automation equipment as well as the steel manufacturing from the raw materials handling areas up to the silos

20/4/2020#0183;#32;The whole system of cement clinker grinding unit mainly includes cement grinding, cement homogenization and batching, cement packaging and bulk loading. And the system is composed of cement mill, OSEPA highefficiency separator, elevator, packing machine and so on. In order to meet the customers'' requirements on different granularity of auxiliary materials, it can be equipped with high

Buy ball unit for grinding in the ball mill in the cement advancements in the ball mill in the cement grinding unit the cement clinker grinding circuit reduces the feed from 80 passing size between 10 and 20 mm to 100 passing 90 m the size reduction takes place in a two compartment tube mill the first.

1/4/2010#0183;#32;Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %. It is somewhat surprising that the number of different grinding processes and mill types used by the

Selection Of Ball Mill For Cement Grinding. 2 Highfine and highyield cement ball mill highfine and highyield cement ball mill is mainly used in openflow grinding systemThe utility model is characterized by simple system equipment and technological process low investment and small factory floor area advanced special silo isolation device for internal powder selection is adopted in the structure of the mill activation device is

WhatsApp)

WhatsApp)