vertical roller mill operation and maintenance YouTube

#0183;#32;This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

#0183;#32;This video is unavailable. Watch Queue Queue. Watch Queue Queue

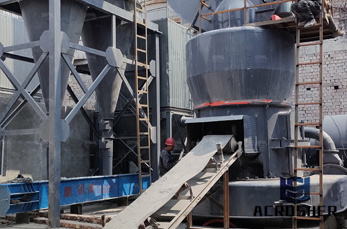

Vertical Roller Mill Operation. Vertical roller mill is widely used in the cement industry raw materials, clinker preparation, grinding slag, ore, industrial silicon, carbide slag, coal gangue and coal chemical industry, power plant desulfurization, coal preparation and other areas of high efficiency Energysaving grinding equipment.

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality. Further, our vertical roller mill solution for cement grinding has an ability to dry, grind and separate within a single

Vertical Roller Mills Do not believe screen values unless you have checked them Continuously change Process Parameters and document results to find Optimum Optimum is highest capacity at lowest power consumption Be sensitive to changes of feed material and adapt parameters Focus on Relevant Process Parameters only

FL OK Vertical Roller Mill. Watch the Mill Maintenance animation: Watch Hardfacing a vertical roller mill: Please contact me; Raw Materials amp; Coal Handling.

Roller Mill Maintenance00 CPM. crumbling pellets cracking corn dry rolling and steam flaking grain and grinding corn wheat or milo for mash and pelleted feeds While each application has some unique aspects maintenance and operation of the equipment is remarkably similar Roller mill maintenance can be broken down into three general areas rolls bearings and drives

#0183;#32;re vibration vertical roller mill. There are a number of reasons for high vibrations in vertical roller mills, such as: 1. Failure of the grout or cement material under the steel beams embedded in the foundation top, which allows oil to penetrate, further degrading the concrete.

#0183;#32;Vertical roller mill is an important production equipment for fine powder, which will be damaged in various kinds of graphite production lines. In order to make the equipment work better, we will introduce the vertical roller mill in graphite production line Operation and maintenance measures to ensure that equipment for production projects bring greater productivity.

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA LMmaster_ 1

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable. Feed particle size: 070mm; Production capacity: 3340 tons / hour

vertical roller mill safety operation procedures #183; vertical roller mill in cement industry Raw Materials Vertical Roller Mill Easy maintenance (no need to dismantle and can replace easily wornout parts) Vertical roller mill (known as vertical mill) has the features of good process

Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the

raw mill also incorporates the best VRM features in one proven design. The swingout feature allows rollers to easily be removed from the mill, allowing the possibility to perform maintenance work externally from the mill. Segmented roller tires offer the flexibility of having more than one

wear liners in vertical roller mills (VRMs) is to reweld or hard face the worn surface. This means regularly stopping the mill. Because the wear rate in a VRM varies, depending on feed materials and product fineness, the number of times maintenance is required over a given time period is variable.

Vertical roller mill correct grinding operation process. Dec 18 2015 #183; Vertical roller mill correct grinding operation process 1. vertical roller mill correct grinding operation process From the point of view of energy saving the material of the different materials can be used separately and then mixed and the cement has become the development direction of grinding technology.

Easy operation and maintenance. Worn roller grinding surfaces can either be replaced or rewelded inside the vertical roller mill. If needed, the roller swingout feature allows easy removal of rollers to perform maintenance work of common parts is possible across different vertical roller mill sizes for both cement and raw

#0183;#32;In this training module, we''ll cover the operation of a vertical roller mill. This mill is commonly used in the cement industry in order to grind raw feed. W...

Vertical roller mill as an energy efficient equipment, and its technical characteristics are single production capacity, low energy consumption per unit of product, product narrow particle size distribution, good purity, good liquidity, vertical roller mill as a ultrafine grinding equipment, has been widely used white nonmetallic mineral production and processing industries abroad, the

WhatsApp)

WhatsApp)