How Cement Is Made | HeidelbergCement Group

Extracting raw material I: blasting and ripping. The most important raw materials for making cement are limestone, clay, and marl. These are extracted from quarries by blasting or

WhatsApp)

WhatsApp)

Extracting raw material I: blasting and ripping. The most important raw materials for making cement are limestone, clay, and marl. These are extracted from quarries by blasting or

Cement manufacturing raw materials. If you happen to be a geologist, the raw materials quarry is probably the most interesting part of a cement works, maybe unless you view the clinkering process as igneous rocks in the making. The most common raw rock types used in cement production are:

Manufacturing process Step 1: Extraction of raw materialsThe raw materials needed to produce cement (calcium carbonate, silica, alumina and... Step 2: Raw grinding and burningVery fine grinding produces a fine powder, known as raw meal, which is preheated and... Step 3: Cement grinding and

What Is the Cement Manufacturing Process? (with pictures)

The most common raw rock types used in cement production are: Limestone (supplies the bulk of the lime) Clay, marl or shale (supplies the bulk of the silica, alumina and ferric oxide) Other supplementary materials such as sand, fly ash/pulverised fuel ash (PFA), or ironstone to achieve the desired bulk composition.

extracting raw material for cement manufacturing. Stage of Cement Manufacture There are six main stages of cement manufacturing process Stage 1 Raw Material ExtractionQuarry The raw cement ingredients needed for cement production are limestone calcium sand and clay silicon aluminum iron shale fly ash mill scale and bauxite The ore rocks are quarried and crushed to smaller pieces of about

Raw materials used for manufacturing of Portland cement are found naturally in the earths crust. It is made primarily from calcareous and argillaceous materials and gypsum. Calcareous materials contain limestone or chalk while argillaceous materials comprise an oxide of silicaalumina and iron. Both are found as clay or shale.

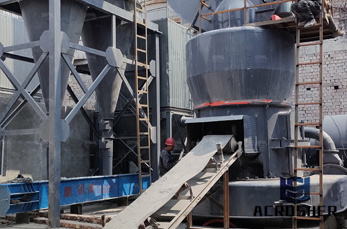

cement raw material crusher ofspescaracolli. Cement Manufacturing Process Flow Chart . In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc. Limestone is the main raw material for cement production, each producing a ton of clinker needs about tons of limestone, more than 80% of raw material is limestone.

Cement manufacturing process amp; what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method).

NOORULAMIN et al.,, Vol. 34, No. 1, 2012 47 Investigation of Raw Material for the Manufacturing of White Cement in Darukhula Nizampur Khyber Pakhtunkhwa Pakistan 1NOORULAMIN*, 2KHURSHID ALI AND 3TIR SH 1Department of chemistry, Abdul Wali Khan university, Mardan, Pakistan. 2Institute of Chemical Science, University of Peshawar, Pakistan.

Cement Extraction and processing BritannicaCement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by . Largescale crushing amp; screening amp; milling plants. Offer efficient, costeffective services for you. Extracting Raw Material For Cement Manufacturing

Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such

#187; Online Training #187; Selecting and using raw materials for cement manufacture Selecting and using raw materials for cement manufacture Course Introduction and approach A new, instant access, online course, comprising of 14 lectures covering all aspects of raw material exploration, planning, extraction and preparation for use as cement clinker kiln feed.

Manufacturing process Ciments Hoffmann. A clean and revolutionary cold manufacturing process. Hoffmann Green has initiated a technological breakthrough based on changing the composition of cement so that it does not contain clinker, the main source of CO2 emissions in traditional cement production, as well as creating a cold and clean cement manufacturing process (no firing of raw materials).

#0183;#32;The cement manufacturing process involves several key steps, including preparing the raw materials, grinding the materials together, heating the newly formed clinker in a kiln, and finishing the cement with fine of the main ingredients used to make cement include limestone, clay, shale, iron, and manufacturing techniques will use either wet or dry grinding, but

Download this stock image: Extracting raw material from quarry for cement manufacturing KMR5MN from Alamy''s library of millions of high resolution stock photos, illustrations and vectors.

In the cement industry, the quarry is the extraction method for the production of raw materials in the cement manufacturing process. Quarry extraction describes the extraction of rocks on the surface, while openpit extraction describes the extraction of minerals on the surface.

Cement Manufacturing Plant Project Report: Industry Trends, Manufacturing Process, Machinery, Raw Materials, Cost and Revenue WDRB 41 Louisville News Guidelines for CoProcessing Fuels and Raw Materials

Principal raw material (Lime or calcareous component) Limestone and chalk are the lime containing compounds. Calcite and aragoniteare the purest grades of limestone. Limestone is hard while clayis soft and hence does not require blasting during quarrying.

Aug 30, 2012#0183;#32;Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite.

WhatsApp)

WhatsApp)