(PDF) Online Optimization of a Gold Extraction Process

Jun 29, 2017#0183;#32;A typical gold ore processing plant makes use of . comminution, sizing, gravity concentration, and dewatering . A dilute cyanide solution is an efficient solvent of gold

WhatsApp)

WhatsApp)

Jun 29, 2017#0183;#32;A typical gold ore processing plant makes use of . comminution, sizing, gravity concentration, and dewatering . A dilute cyanide solution is an efficient solvent of gold

Process Introduction. CIP (Carbon in pulp) process is a high efficient method to leaching and recovering gold from gold ore, The most different from CIL process is in CIP process, gold leaching and adsorption are separated, first leaching, and then adsorption. Now it is being replacing by CIL process progressively.

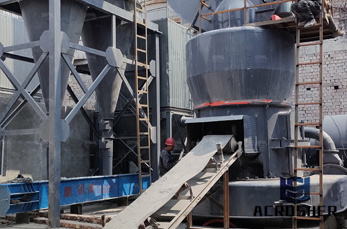

A gold processing plant in Song County, Henan Province adopts flotation + cyanide leaching + carbon slurry adsorption process. The final product is goldloaded carbon, and cyanide tailings are directly discharged after pressure filtration. In actual production, the concentrating plant often has the phenomenon of process interruption and operation stoppage due to equipment failure, which greatly

Gold CIL process (carbon in leach) is an efficient method of extracting and recovering gold from its ore. By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lowers the gold mining operation cost and increases gold recovery rate to a degree of 99%. It is the first choice of modern gold mining and gold beneficiation plant.

SPEEDMINER#174;mobile plants produced in 18 Models, for both Alluvial and Hard Rock mining operations, with total capacity range of 5 120 Tons/Hour (20 480 m3/Hour), are configured as a complete selfsufficient plant, designed for continuous recovery of gold, diamonds, gemstones, and other Metals amp; Minerals, to the micron size.

Jan 01, 2016#0183;#32;In this categorization, freemilling ore is defined as yielding over 90% recovery under conventional cyanidation conditions, while those ores that give acceptable economic gold recovery only with the use of significantly higher chemical additions (, cyanide, oxygen, carbon) are

Mar 15, 2018#0183;#32;A 6500 TPD Gold amp; Silver Processing Plant will cost millions of dollars where small mineral pilot plants may cost hundred of thousands and a portable pilot plant

high efficient gold dust tin ore processing plant. Efficient Thickener. Efficient Thickener. Hydraulic Motor Driving Center Thickener. Hydraulic Motor Driving Center Thickener. Grid Type Ball Mill. Grid Type Ball Mill. Submerged Slurry Pump. Submerged Slurry Pump. Agitation Tank For Chemical Reagent.

EXPLORER#174; is a Portable Processing Plant exclusively designed, developed and patented, with the latest minerals processing technology by DOVE, and supplied in various integrated configurations for efficient and professional Alluvial mining operations of gold, diamonds and other metals and minerals.

efficient gold processing plant for sale thickener for sale in saudi arabia; Gold Ore Concentration Plant Gold ore whose types of deposits are diverse and complex is the mineral assemblage of gold. With features of chalcophile affinity and high melting point, the gold ore includes conglomerate type, porphyry type, quartz vein type and

The EXPLORER #174; Processing Plants are Portable Wash Plants exclusively designed, patented and developed by DOVE Equipment amp; Machinery Co., Ltd., for surface mining in exploration and pilot mining operations of alluvial Gold, alluvial Diamond, Gemstones, and other Alluvial (Placer) metals and minerals.. EXPLORER #174; Portable Alluvial Processing Plants (Portable Wash Plants) are produced

Gold ore. Prominer maintains a team of senior gold processing engineers with expertise and global experience. These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of optimal and costefficient process designs.

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

20 #0183;#32;21 Gold Ores Processing Companies in the United States. Search or browse our list of Gold Ores Processing companies by category or location.

CIL (Carbon in Leach) process is the most efficient method to leaching and recovering gold from gold ore, The most protruding features is that leaching and adsorption are carried out at the same time, which greatly saves the cost of construction and operation. It has become the first choice of modern gold mining and processing plant design.

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilotplant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of a larger plant or for processing ore

The hashing stage (corresponding to metal extraction and recovery stages) is a little more complex for gold ores, as the optimal process flowsheet selection choice is heavily dependent on a good understanding of two fundamental geometallurgical parameters, the gold mineralogical associations, and the gold particle size and liberation

A blockflow diagram of a typical CIP plant for a nonrefractory gold ore is shown in Figure 2. Table I and Table II illustrate the capital and operating cost breakdowns for a typical South African gold plant. These figures are not a standard but reflect the nature of the ore and the design basis for a particular situation.

Three ways for gold ore processing : cil amp; cip washing machine amp; gold Gravity flotation. please see the contents below ore CIL amp; CIP process Gold CIL (Carbon in Leach)leaching process, namely Carbon leaching extraction, it is a process of adding activated Carbon to the slurry and simultaneously leaching and

EXPLORER #174; Portable plants are produced in 8 models, for both Alluvial and Hard Rock gold mining operations.. For application of Alluvial (Placer) deposits of gold, other metals and minerals it is offered in 5 models, capacity range of 1060 Tons/Hour solids (40240 m3/Hour slurry).. For application of Hard Rock (primary) deposits of gold

efficient low consumption gold processing plant. There are forty years of manufacturing history, with three major production bases,over 160 senior Ramp;D engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ advanced technology and craftsmanship, adopting

WhatsApp)

WhatsApp)