Study On The Performance Of High Chromium Cast Iron Balls

The effect of carbide content on the wear resistance of high chromium cast irons was evaluated by means of ball mill testing. Martensitic cast irons containing from 13 to 41% carbide volume

WhatsApp)

WhatsApp)

The effect of carbide content on the wear resistance of high chromium cast irons was evaluated by means of ball mill testing. Martensitic cast irons containing from 13 to 41% carbide volume

A preformed item of semirigid material designed to retain, position, fasten, or support other items, such as cable(s), access cover(s), by its own inherent spring action. It may be fastened to a structure by bolt(s), clip(s), screw(s), and the like. For items conducting electric current, see CLIP, ELECTRICAL or CLAMP, ELECTRICAL.

The ball mill abrasion test (BMAT) promises to offer accurate prediction of relative service lives of wearresistant alloys for liners and grinding media in mineral grinding environments.

SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind applications in nominal sizes from to in diameter. CHEMISTRY An individual chemical profile has been developed for each diameter ball to correspond with the requirements for heat treatment.

China leading provider of Steel Grinding Balls and Forged Grinding Balls, Jinan Dragon Steel Balls Co.,Ltd is Forged Grinding Balls factory.

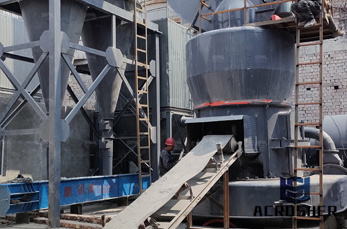

Grinding ball copper ball copper concentrator lm heavy industry is a manufacturers of jaw crusher cone crusher sand making machine vsi impact crusher mobile crusher plant and vertical mill ultrafine grinding tricyclic mediumspeed microgrinding coarse powder pulverized coal mill raymond mill hanging roller mill.

The copper concentrator in Pinto Valley, Arizona processes a % grade copper ore from a nearby open pit mine. The unit operations consisting of crushing, grinding, and flotation process about 65,000 tons of ore per day in six overflow ball mills. The concentrate is transported to a

A tubular shaped item with a round or hexagon peripheral shape having two flat bearing surfaces perpendicular to the axis of the centrally located hole. It is designed to maintain a predetermined distance between assembled parts. The item may be with or without flange(s) of any peripheral shape.

Balls for use in mineral processing ball milling operations are designed for maximum abrasion resistance using high carbon content and high hardness levels. PRODUCT SPECIFICATIONS. SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind applications in nominal sizes from to in diameter.

The ball mill grinding ball on the market now can be divided into two kinds according to the manufacturing process: Cast grinding Ball and forged steel ball, but their wear degree is not the to crushing and pulverizing materials, grinding balls need good abrasion resistance and enough impact toughness, and require steel balls cannot be broken, ball mill grinding balls can be

Overall Service Solution: According to specific circumstances and working conditions in the concentrator, HMR group significant expert team taking advantage of highquality independent research and development products, advanced cuttingedge technology, customized services and the application of advanced management system, through dynamic integration of various resources, helping

grinding ball copper concentrator . Second Hand Concrete Batching Plants For Sale In Malaysia. Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated,

Mt Isa Mines (MIM) Copper Concentrator used chrome balls to replace the normal grade steel balls as grinding media in one of the two secondary ball mills in. Read more Consumable unit cost versus metallurgical performance: the saimm

Effect of ball size on the performance of grinding and flotation Know More. 18 Jul 2013 At the Sarcheshmeh copper mine, 41 000 t ore per day with an average grade Grinding is effected in eight parallel lines of 8 #215; 5 m ball mills in a closed c. Transactions of the Institutions of

Rolled Forged Steel Grinding Balls newproduct . FEATURES Superior raw material advanced automatic equipment unique heat treatment technique and strict quality control system make better performance for the whole hardness of our hardness of our grinding steel ball with surface hardness as high as 5865HRC volume hardness es high 5664HRC hardness distribute uniform impact toughness bigger

Our forged steel grinding balls commonly used lowcarbon alloy, high manganese steel, high carbon and high manganese alloy steel. On the basis of these material we have developed a series of competitive and efficient patent forged grinding balls.

Concentrator Gold Glass Forged Steel Balls For Fine 10l Comprehensive Canton Fair Factory Efficient High Efficiency Ball Mill, Find Complete Details about Concentrator Gold Glass Forged Steel Balls For Fine 10l Comprehensive Canton Fair Factory Efficient High Efficiency Ball Mill,High Efficiency Ball Mill,High Efficient Ball Mill,Factory Ball Mill from Grinding Equipment Supplier or

#0183;#32;Grinding Ball, ALLSTAR Grindingball, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tons.

Changshu Feifan Metalwork Co.,LTD, China Experts in Manufacturing and Exporting grinding ball, mill ball, forged ball

WhatsApp)

WhatsApp)