How to calculate cement ball mill capacity Quora

Ball Mill Design/Power Calculation

WhatsApp)

WhatsApp)

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum chunk size, product size as P80 and maximum and finally the type of circuit open/closed

Ball mill capacity, how to calculate. Ball PSP Engineering. Main characteristics of ball mills seated on shoetype bearings. Low operation and maintenance cost.

find ball mill plants in zimbabwe; find ball mill plants in zimbabwe. Where can I buy iron ore crushing plant in Zimbabwe? Quora. LiuYuXi, Top aggregate crushing equipment manufacturers. 41 Views By breaking crude ore, and then through the medium and fine crushing material size to fit into the ball mill.

Capacity Of Ball Mill Cargotrainingcenter. 10 tonne per hour ball mill gold or a 300ton plant for the ball mill grinding to process the concentrates dry process ball is 030 ton per hour ball widely applied in cement chemical industry have dry process and to grinding.

You can ask your vendor who made this machine. Its difficulty to calculate capacity of a machine or maximum capacity. Its depend on a lot of parameters. But you

Capacity (25% of total) Total Volume WET Working Capacity (60% of total) rpm DRY milling 60% of critical Gear amp; Pinnion Drive used on Larger Mills JH 32014 Talk with the Experts sales _____ Since 1911 phone fax B Ball Mill Capacity amp; Dimensions

Ball mill capacity, how to calculate Coal Surface Mining western posts related to 10 tonne per . Get Price. Towards optimising ballmilling capacity: Effect of lifter design. The effect of liner/lifter profile on kinetics of batch grinding and the milling capacity in general was assessed using monosize quartz material of 30 #215;amp;

ball mill capacity how to calculate; Christmas special! Limited time offer, price concessions, up to 66%, come and consult!Inquiry. Clasificador Espiral . Como parte importante de la

Show all discussions about to calculate ball mill capacity in the field of powder/bulk handling and progressing.

Ball Mill Capacity Calculations. milling cutters are cutting tools typically used in milling machines or machining centres to perform milling operations and occasionally in other machine toolsey remove material by their movement within the machine e, a ball nose mill or directly from the cutters shape e, a form tool such as a hobbing cutter.

cement ball mill capacity calculation . Jan 14, 2014 14 Jun 2013 Get Price ball mill grinding capacity calculation 31 Dec 2013 cement ball mill capacity Zenith. 14 Jun 2013 Get Price Calculate... Get Price. Rem: Revista la de Minas Simulation of a ball mill operating

The sizing of ball mills and ball milling circuits from laboratory grinding tests is largely a question of applying empirical equations or factors based on accumulated experience. Different manufacturers use different methods, and it is difficult to check the validity of the sizing estimates when estimates from different sources are widely divergent. It is especially difficult to teach mill

Ball Mill Capacity Calculation mineral processing system .. CachedMore information of ball mill capacity ball mill capacity 5kg, cement, lime, plaster mortar. pharmacology vkscientific p4 ball millFind the Right and the Top Ball Mill Capacity Calculation for your coal handling plant! Read more

In the ball mill, Lead is converted to Lead Oxide, by grinding and oxidation process, which is an exothermic process. In this process, heat is generated and temperature of oxide is increased, to control the temperature with in the operating range of 115 to 135C, the ball mill temperature is controlled with constant flow of air and with the water spraying system controlled through solenoid valve.

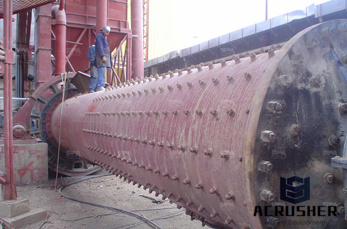

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls.

Cement Mill Calculation Pdf Cement mill calculationcement mill calculation pdf. calculation for cement mill pdf onlinedlwinternship cement ball mill design capacity calculation cement mill design calculation Grinding Mill China. 201836 This MTW series milling machine is designed by our experts, according to collected advices from customers'''' longterm experiences.

#0183;#32;Optimization of Cement Grinding Operation in Ball Mills. Contact Us #187; . Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills.

Ball Mills an overview ScienceDirect Topics. It is possible to make an approximate calculation of the capacity of a ball mill by means of the equation: N = ( D 3 L + L n) 1 1 2. where is the apparent density of the balls; l is the degree of filling of the mill by balls; n is revolutions per minute; 1, and 2 are coefficients of efficiency of

Rotating Large Capacity Ball Mill Grinder Crushing Rock Ore at a Mine Koop deze stockfoto en ontdek vergelijkbare foto''s op Adobe Stock

A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expressed as a percentage of the net internal mill volume (inside liners). B) Overflow Discharge Mills operating at low ball fillings slurry may accumulate on top of the ball

WhatsApp)

WhatsApp)