UltraTech Magdalla Cement Grinding Mill

17/4/2019#0183;#32;Type: Cement Grinding Mill. Area: Marashtra. Annual Production: million tonnes of cement. Owner: UltraTech Cement Limited. Shareholders: Aditya Birla Group

WhatsApp)

WhatsApp)

17/4/2019#0183;#32;Type: Cement Grinding Mill. Area: Marashtra. Annual Production: million tonnes of cement. Owner: UltraTech Cement Limited. Shareholders: Aditya Birla Group

Roller Press with Ball Mill Cement Grinding Systems Selection Principle. As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the client. If you still have questions about the cement grinding system, or are interested in something

Feb 10, 2016#0183;#32;planning to put up a new cement grinding plant using Vertical Roller Mill(300350 TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution and how does it compare

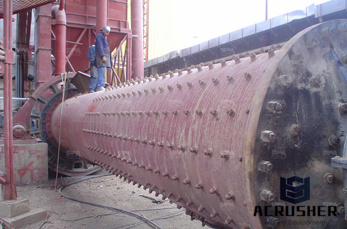

18/7/2016#0183;#32;Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber. It is lined with classifyingtype mill shell liners and provided with finer ball charge. Classifying

A #163;20 million project to install a giant cement grinding mill and upgrade the rail loading facilities at Padeswood works in north Wales is under way. Preliminary construction work began in November after Flintshire councils planning committee unanimously approved the development technical director Gareth Price said: Securing planning consent got us over a critical

10/2/2016#0183;#32;experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 TPH) and before implementing the project, we would like to gather as much information regarding the actual operation of this mill during cement grinding and the quality of the product in terms of the fineness/particle size distribution

Key words: power draw, cement, dry grinding, ball mill INTRODUCTION Energy is the most important cost item in a cement plant. About 60% of the electricity consumption for cement production is used for grinding the raw material and cement clinker (Zhang et. al., 1988). Annual cement production is approximately billion tons and the grinding process consumes nearly 2% of the electricity

Mar 03, 2015#0183;#32; Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many ki...

Due to the use of habit, ball mill, roller press as the traditional ball mill grinding equipment, which has more than 100 years of history, especially the low cost, the ball mill cement sphericity Gauguin is let very favour of cement plant. With the development of the times, although the ball mill is very harmful to the environment in the use of the process, but due to lack of funds and

21/4/2019#0183;#32;Type: Cement Grinding Mill. Area: Marashtra. Annual Production: million tonnes of cement. Owner: Ratnagiri Cement Works. Shareholders: Ultra Tech Cement Limited (Aditya Birla Group) Activity Since: 1999 Contact Coordinates:, Address: MIDC Industrial Estate, Zadgaon Block, Ratnagiri District, 415639 Marashtra. Email: Phone: +91 (2352) 221 807 . Web:

In any cement grinding circuit, it is necessary to grind clinker, gypsum, and sometimes other additives in the proportions required at a predetermined fineness. The fineness is usually defined by the specific surface area of the cement measured in m#178;/kg or cm#178;/g. With highefficiency separators, it is normal to grind cement in a closedcircuit system due to energy consumption savings. Safety

Type: Cement Grinding Mill. Area: New South Wales. Products: Cement. Owner: Maldon Cement Works. Shareholders: Boral Limited. Activity since: Contact Coordinates:, Address: Cormorant Road, Kooragang Island NSW 2304 New South Wales. Email: Phone: +61 (2) 9033 4000 (ProspectNSW Head Office) Web: Wikipedia: Boral Notes: Former Blue Circle Southern Cement

Jul 18, 2016#0183;#32;Operation and Elements of a Closed Circuit Ball Mill System. Cement ball mills typically have two grinding chambers. The first chamber is filled with larger diameter grinding media and lined with lifting liners. The first chamber coarsegrinds the feed material and prepares it for the second chamber. The second chamber is the fine grinding chamber.

A cement mill (or finish mill in North American usage ) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

WhatsApp)

WhatsApp)