Cement Plants located in United States The Global

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report, 13th Edition.

WhatsApp)

WhatsApp)

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report, 13th Edition.

A concrete plant, also known as a batch plant or batching plant or a concrete batching plant, is equipment that combines various ingredients to form of these inputs include water, air, admixtures, sand, aggregate (rocks, gravel, etc.), fly ash, silica fume, slag, and concrete plant can have a variety of parts and accessories, including: mixers (either tilt drum or

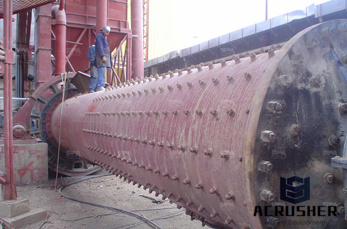

Cement grinding unit is a vital link in the cement production line and the most energyintensive process. The main function of cement grinding plant is to grind cement clinker (and gelling agent, performance adjusting material, etc.) into a suitable particle size (expressed by fineness, specific surface area, etc.), form a certain particle gradation and increase its hydration area.

The Zero Emission Eco Town (ZEET) System is an integrated system of cement plant and incineration plant. The ZEET System treats refuse and sludge hygienically, and processes into energy and raw materials for cement manufacturing. This system reduces the fuel consumption for cement manufacturing by obtaining energy from gasified refuse.

Cement plant laboratories check each step in the manufacture of portland cement by frequent chemical and physical tests. The labs also analyze and test the finished product to ensure that it complies with all industry specifications. The most common way to manufacture portland cement is through a dry method.

#187; what are the machine required for granite plant #187; jaypee cement job in wanakbori #187; chemical engineering plant cost index 2013 #187; gold dredges for sale in georgia How to Set Up and Run a Quarry Plant Stone Quarry Plant

Plant Bio. Portland cement is used in various applications, from concrete, mortar and render to the manufacture of precast units such as blocks, bricks, pipes and tiles. *The packaging design shown is for illustrate purpose only. The actual product will be delivered in see through bags.

The Schelklingen cement plant has been operated for more than 100 years and currently provides kiln production capacity of approx. 3,500 tons of clinker. Since 1987 HeidelbergCement has been using different CEMAT versions in this cement plant location.

what machinerequired for cement plant cement plant equipments manufacturer and suppliers of clinker Cement Plant Equipments We known for quality equipments manufactures and supplier of clinker grinding units rotary kilns crushers conveyors for cement . Get Price.

#0183;#32;BUA Cement has signed an agreement with Sinoma CBMI of China for the construction of three new cement plants of three million tonnes each per annum, a project valued at A statement by the

If a cement plant disposes of municipal waste and car batteries for its local community, generates electricity from its solar or wind plant for a nearby city and uses its CO 2 to either produce biofuels, plastics or baking soda is it still just a cement plant? The pivot by building materials manufacturers in recent years from a focus on cement

Ashoka''s cement plant unit has continued focused on objectives of product improvement and quality. In our entire turnkey cement plant equipments and machinery, we supply a complete assembly consisting of different machines and equipment, which facilitate the plant to execute efficiently and manufacture a betterquality completed product as per the international quality standards.

WhatsApp)

WhatsApp)