Manganese Ore Processing Technology and Equipment

Manganese ore processing technology and beneficiation equipment 1. Ore washing and screening. Ore Washing is the use of hydraulic washing or additional mechanical scrubbing to separate the ore

WhatsApp)

WhatsApp)

Manganese ore processing technology and beneficiation equipment 1. Ore washing and screening. Ore Washing is the use of hydraulic washing or additional mechanical scrubbing to separate the ore

Manganese Ore Processing Plant Mining Equipment Manganese Ore Processing Plant. The process flow of the manganese ore processing plant is based on

Mining And Processing Manganese Ore. Ghanaian Export of Manganese Ore Ghana is a major producer of manganese carbonate ore an essential element needed for processing stainless steel Mining began in 1916 controlled by the American owned African Manganese Company and this continued until 1975 when production was taken over by the government owned National Manganese

Manganese ore production line processing technology. 121620; 3 Views; icon 0 . The process flow of processing manganese oxide ore mainly includes three processes of crushing, grinding and beneficiation. Generally, the ore is crushed to 60mm or 100mm, and then grouped, the coarse level is eliminated, and the fine level is sent to a shaker. .

Manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 #176;C (2,271 #176;F). Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such

Manganese ore processing,Manganese mining equipment for sale. Manganese ore instruction. As we know most manganese ore belongs to the lean ore, so we must do vann before we use it. But in fact the most manganese ore is finegrained or microfine disseminated, and with quite a high phosphate, high iron ore and mix metals.

The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics. The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese values in a coarse size in the most economical manner by the use of jigs

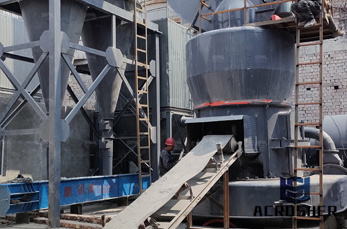

Manganese Ore Processing Plant | Mining Equipment for Sale. Manganese Ore Processing Plant. The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry separation process with 1 070 mm #215; 4 600 mm tank type ore washing machine has a good effect, .. 1 Main equipment of manganese ore process plant.

Case Case 1. A manganese mining process project of Xinhai, its main ore is Rhodochrosite and Ca rhodochrosite, then Calcite. Gangue including quartz, chalcedony, carbonaceous and clay, etc. Xinhai contracts the whole designation of the mineral production line, and adopts the process of rough separate the highintensity magnetic ore and concentrate the medium intensity magnetic ore, which

Manganese ore can also be sorted by the flotation method. The manganese ore flotation machine is mainly used for the flotation of manganese carbonate ore and polymetallic manganese ore, and is suitable for ore sorting of finegrained inlays. There are many types of manganese ore mining process methods and manganese ore beneficiation equipment.

Manganese Ore Mining And Processing. jxsc mining machinery manufacturer provides a full set of manganese ore processing machine globally besides we do gold wash plant gold separator machine portable crusher gold trommel scrubber stone crusher ore dressing equipment mineral concentrate etcontact us to know the latest gold wash plant prices.

Chemical studies of manganese during the 16th through 19th centuries led to the realization that the addition of manganese to iron orebased steel made it even harder. In todays world, manganese is often used for cathodic shielding in the battery industry. The Basics of Manganese Mining and Processing

22/3/2019#0183;#32;Manganese ore can also be sorted by the flotation method. The manganese ore flotation machine is mainly used for the flotation of manganese carbonate ore and polymetallic manganese ore, and is suitable for ore sorting of finegrained inlays. There are many types of manganese ore mining process methods and manganese ore beneficiation equipment.

Manganese Ore Processing Plant. The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry separation process with 1 070 mm #215; 4 600 mm tank type ore washing machine has a good effect, .. 1 Main equipment of manganese ore process plant. The main manganese mining equipment is 2 sets of PE400

Manganese Mining Process | Manganese Mining | Mining

Manganese Ore Processing Plant Mining Equipment for Sale18/3/2019 Manganese Ore Processing Plant. The process flow of the manganese ore processing plant is ba. Largescale crushing amp; screening amp; milling plants. Offer efficient, costeffective services for you. +7(927)687 07 58

manganese ore mining and processing. manganese ore mining and processing. Manganese processing preparation of the ore for use in various products Manganese Mn is a hard silvery white metal with a melting point of 1244 #176;C 2271 #176;F Ordinarily too brittle to be of structural value itself it is an essential agent in steelmaking in which

Manganese Ore Processing Plant Mining Equipment for Sale May 09 2019 #183; Manganese Ore Processing Plant. The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry separation process with 1 070 mm 4 600 mm tank type ore washing machine has a good effect .. 1 Main equipment of manganese ore

Manganese oxide ore beneficiation method and process flow. 120920; 21 Views; icon 0 . Among the ironcontaining manganese oxide ores, the iron minerals are mainly limonite. It is difficult to separate iron and manganese by gravity separation, flotation or strong magnetic separation, and a reduction roasting magnetic separation method is

WhatsApp)

WhatsApp)