Finescreening of coal : testing of the sieve bend (eBook

Additional Physical Format: Print version: Geer, Max Richard, 1912Finescreening of coal (OCoLC): Material Type: Document, Government

WhatsApp)

WhatsApp)

Additional Physical Format: Print version: Geer, Max Richard, 1912Finescreening of coal (OCoLC): Material Type: Document, Government

Screening of coal stoker. Production and gasification tests of coal fines/c...1/4 inch is removed by screening prior to gasification in order. Read more

Fine coal dry classifiion and separation. The 500mm coal can be screened into 506mm and 60mm coal by QGS2020 type pianowire probability screen (Yaomin et al., 1998). Then, the 06mm coal is first classified into two fractions: the coal fines with the size below and the fine coal with the size between and 6mm. In . Get price

Finally, screening processing on a laboratory prototype was conducted to draw the conclusion that the developed CFS also has a high sieving efficiency for the fine and moist coal. View Show abstract

Coal screening equipment from Multotec delivers maximumefficiency classification and separation solutions through magnetic, flotation, gravity or cyclonic action processing.. Our coal screening equipment, rated among the highest quality coal screening equipment internationally, is used in coal preparation plants (MCPP), modular coal preparation plants (MCPP) and are ideal for coal cleaning

Fine coal screening is especially important and new fine coal centrifuges have been developed which can drastically reduce the amount of water in your waste coal product. By sifting back through old coal waste deposits with efficient coal screeners, useful material can be recovered.

For years fine dry screening has been the domain of woven stainlesssteel wire mesh. For as many years fine dry screening has proven difficult due to several factors. These factors include but are not limited to the following: KELLEY, C. Fine dry screening with urethane screen surfaces.

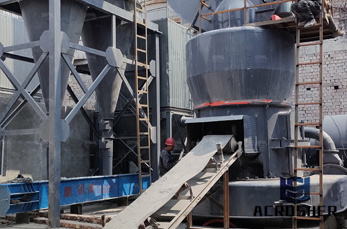

want to crushed stone business screening of coal fines. There are forty years of manufacturing history, with three major production bases,over 160 senior Ramp;D engineers and 600+ large and mediumsized digital processing equipment, The firstline technicians and professional aftersales service personnel up to 2,300+ and 200+ respectively.

recovering energy value from fine coal discards generated by the South African coal mining industry. The cost of dewatering or drying these fines lt;150#181;m exceeds the fuel value of the fines. However the quality of these fines is equivalent to that of run of mine coal. These fines

Our screening solutions are ideal for screening, scalping, sizing and dewatering a widerange of applications to meet the requirements of contractors, miners and quarries. Pilot Crushtec Internationals machines scalp, screen and dewater millions of tonnes of sand, gravel, topsoil, crushed stone, coal, glass, construction and demolition (Camp;D

Welcome to Global Coal Mining Pvt. Ltd. The air current along with the coal fines form suspension media, 50 mm to +6mm will be the feed to the Heavy Media Circuit from the present screening plant,

Screening of Fines. Wet Screening . Dry Screening of Small and Fine Sizes . 9 Gravity Separation Jigs . Introduction . The Jigging Action . 13 Gravity Based Separation of Fine Coal . Introduction . What is Fine Coal? The Issues of Fine Coal Cleaning . Flowing Film Separators .

screening of coal fines Effect of wet screening on particle size distribution and Wet screening is one of the methods used to remove fine material from the coal feed to gasification.

Home gt; NEWS gt; Industry News gt; Screening and Recycling of Fine Coal Powder in Coal Washing Plant. Mining Vibrating Screen. Ideal Screening Equipment Composite Frequency Screen + Read More. Tel: + Mail:business Free Consultation

Apr 06, 2016#0183;#32;Website: This is low cost coal/material screening machine. This machine screens coal with low or no wastage. High quality and heavy capacity.

Nov 21, 2020#0183;#32;; If the screening is not thorough, a part of the fine coal will enter the screening equipment, which will greatly affect the screening effect of TDS. The reliability of screening equipment should be fully considered when selecting it. At present, vibrating screens and roller screens are the most widely used in raw coal screening.

In this way the screen can control pins screening both volumetrically and qualitatively. Fines screening efficiency is typically 80 to 90 percent. This means that sufficient surface area is provided so that 80 to 90 percent of the fines which are present in the roll screen infeed are removed.

Under the Federal Mine Safety amp; Health Act of 1977, all working underground coal miners are eligible for chest xray screening at no cost to them. The screening provided by NIOSH will include a chest xray, a breathing test and a oneonone interview to identify potential health concerns. Typically, the process takes about 30 minutes.

Screening and Grading of Moist Fine Coal. Screening and classification of moist fine coal is a difficulty in screening technology research at home and abroad. As moist fine coal binds to each other, material adheres to the screen surface and blocks the screen hole, thus reducing the effective screening area and screening efficiency.

Preparation of fine coal can cause air pollution if proper dust and gas removal equipment is not installed. The air effluent from a finecoal preparation plant consists of entrained dust, both coal and ash, and various gases, primarily consisting of products of coal combustion from thermal dryers (Leonard, 1979). Sources of particulates include thermal dryers, pneumatic coalcleaning equipment, coal processing

The unique action of the BIVITEC#174; screening deck eliminates blinding by accelerating the coal particles up to 50Gs. This not only keeps the openings free from pegging, but also helps to break up the clumps of waste coal, liberating the fines and allowing them to fall through the screen openings.

WhatsApp)

WhatsApp)