Carbonisation Testing and Research ALS Global

How does coke and coal play into steel making?

WhatsApp)

WhatsApp)

How does coke and coal play into steel making?

Light a small fire directly under the barrel and grill. The heat from the fire will rise and cook the coal, but the lack of airflow through the cylinder will prevent it from igniting. Let the fire burn down after about 30 minutes and collect your coke.

#0183;#32;Quality of coal In either coke or noncoked coal, the quality of the coal affects the quality of the steel. Metallurgical coke is made from bituminous coals by a distillation process. Ash deposited by the coal must be kept to a minimum, preferably below 10% of the original mass.

how to prepare coke from coal in small scale KAMY. Crucible steel Wikipedia Crucible steel is steel made by melting pig iron (), iron, and sometimes steel, often along with sand, glass, ashes, and other fluxes, in a ancient times steel and iron were impossible to melt using charcoal or coal

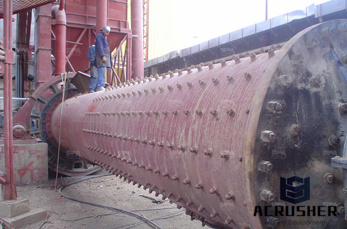

Coal utilization Coal utilization Carbonization (coke making): Coke is the solid carbonaceous residue that remains after certain types of coal are heated to a high temperature out of contact with air. The process of heating coal in this manner is referred to as carbonization or coke making. Hightemperature carbonization, with which this section is concerned, is practiced to produce a coke

1/1/2017#0183;#32;Upon determination of the optimum digestion conditions, larger scale tests to prepare coal digests for assessment as feedstocks for anode grade coke production were conducted using a 2l stirred Parr autoclave (300 g coal: 600 g solvent). After charging and purging with nitrogen, the reactor was rapidly brought to the operating temperature to commence the digestion stage for the specified

Q: After touring the grounds of the historical Coke Ovens Park in Dunlap, Tenn., I wondered how and why coal was turned into coke. They employed more than 300 people at one time. In Granite City

Charcoal Making Method, Coke (Fuel), Coke Manufacturing, Coke Production, Commercial Charcoal Production, Commercial Coal Mining, Fossil Fuel, Guidelines for Small Scale Coal Mining, How to Make Charcoal from Coconut Shell, How to Start Charcoal Making Industry, How to Start Charcoal

The aim of this comparison was to assess to what extent the smallscale soleheated oven can successfully replicate the production of pilotscale oven cokes, and thus be used to rapidly prepare

#0183;#32;Plenty of vids on youtube showing how to make small batches of charcoal often for art use or other uses. I use two food cans, one inside the other (a can of beans may be slightly larger than a can of peas or fruit) fil the smaller can with wood invert the other and sit it top can down in the fire. quick simple and cost nothing.

#0183;#32; Production of coke from selected coal samples. Upon determination of the optimum digestion conditions, larger scale tests to prepare coal digests for assessment as feedstocks for anode grade coke production were conducted using a 2l stirred Parr autoclave (300 g coal: 600 g solvent).

Coal for metallurgical coke production predictions of . A decline in coke production capacity relates to the age of installed cokemaking plants where huge investments would be needed to built new coke plants or renovate the old on The relative importance of an international coke trade is not that high; in 1999 it only accounted for about 5% of total coke production

8/9/2020#0183;#32;A coke produced using a custombuilt soleheated oven and a coke prepared in a pilotscale oven from a matched coal, were compared using a range of analytical techniques. The aim of this comparison was to assess to what extent the smallscale soleheated oven can successfully replicate the production of pilotscale oven cokes, and thus be used to rapidly prepare and screen a wide

22/6/2017#0183;#32;Absolutely scaleable! Scaled down: artists turn willow twigs into charcoal pencils, and primitive campers make char cloth in Altoids tins and shoe polish tins. Scaled up, somebody once posted on turning a burntout (vandalized) dumpster into a room sized retort. 55 gallon steel drums, old water heaters and heating oil tanks are soooo last

Coke is a grey, hard, and porous fuel with a high carbon content and few impurities, made by heating coal or oil in the absence of aira destructive distillation process. It is an important industrial product, used mainly in iron ore smelting, but also as a fuel in stoves and forges when air pollution is a concern.. The unqualified term quot;cokequot; usually refers to the product derived from low

24/4/2013#0183;#32;So coal (as coke) is a reducing agent, a source of energy to drive the process and a source of carbon to incorporate in the steel. Alternative processes need to meet all three functions. This is why you have to do more than just substitute a different energy source. In New Zealand, the coking coal occurs on the west coast of the south island. The bitumen in the coal binds it into lumps in a

7/11/2017#0183;#32;On a small testing scale, coke can be created by the slow heating of coking coal in a refractory lined coal testing oven (CTO) to 1000C for 3 4 hours in the absence of air. The coal softens at a temperature of between 400 500C to form a liquid or plastic phase, agglomerates, swells and particles temperatures of between 450 550C, there is resolidification forming semi

Coke is produced by heating coal fuels; however, these uses of coal are mainly experimental and done on a small scale. Coal Wikipedia, the free encyclopedia in manufacturing and to make coke; Steam coal is a grade use it is sometimes known as seacoal in the Small steam that led to the largescale use of coal, as the

The general procedure for small scale cokemaking is: 1. The coal is crushed to pass a specific target. moisture of the coal is adjusted to a predetermined level. 3. The coal is packed to the target bulk density in a box. 4. The box is pushed into the small scale coke oven set at a predetermined temperature. 5. The charge is pushed 30 minutes after the centre of the charge has reached

Coke Making from Coal : Scope for SSI Ram Pravesh Bhagat National Metallurgical Laboratory Jamshedpur 831 007 Preamble The technological developments have opened up new avenues for small scale industries (SSI). The SSI sector has proved its mettle even in the changed liberalised economic environment of the nation. The SSI sector is riddled with certain problems_ It is therefore

WhatsApp)

WhatsApp)