Industrial IoT Applications For Conveyor Belt DZone IoT

In this post, we take a look at the Industrial IoT applications for conveyor belt systems, specifically the mining, manufacturing, and warehouse sectors.

WhatsApp)

WhatsApp)

In this post, we take a look at the Industrial IoT applications for conveyor belt systems, specifically the mining, manufacturing, and warehouse sectors.

Australian belt correction system manufacturer Track Straight has taken the guesswork out of conveyor alignment and spoke to Mining Technology about how theyre saving operators money. How it works The companys manual conveyor belt correction systems allow operators to adjust the tracking frame via a rotating hand wheel while the conveyor is stilling running.

#0183;#32;Australian belt correction system manufacturer Track Straight has taken the guesswork out of conveyor alignment and spoke to Mining Technology about how theyre saving operators money. How it works The companys manual conveyor belt correction systems allow operators to adjust the tracking frame via a rotating hand wheel while the conveyor is stilling running.

Some coal mining began before 1900, but the most productive coal mining techniques didnt develop until after the turn of the century, including the first conveyor belt and mechanized coal loading. Bituminous coal overtook anthracite in the mid1800s. In the 1960s, smaller coal companies merged into larger, more diversified firms.

A global leader in bulk handling equipment has introduced an innovative technology that uses the kinetic energy from a moving conveyor belt to generate enough power to run a wide variety of

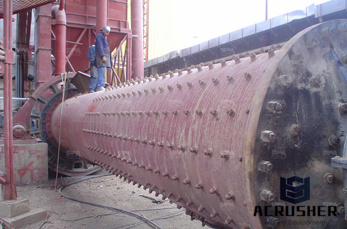

#0183;#32;Robust conveyor belt systems for mines and tunnels enable operations to run smoothly, with throughput being reliably transported between processes. Carroll Technologies distributes conveyor belt systems from a range of trusted manufacturers, including Goro,

As a development partner and original equipment supplier in the mining sector, we supply highend technologies for a variety of applications. While our conveyor belts enable the efficient transport of materials, our drive belts and undercarriages ensure optimum performance in construction vehicles. As a system supplier, we fully equip systems and

Conveyor Belt Support System (from ) Pulleys: Conveyor belt systems have at least two pulleys to control belt movement, a drive pulley and tail or return pulley. In between them are idler or dummy pulleys that are moved by the belt. The drive pulley pushes or pulls the load, while the tail pulley returns the belt.

#0183;#32;One emerging solution is the advancement in pallet conveyor systems. These systems are ideal for applications that require precise movements and exact positioning of parts. Robotics engineers can program a pallet system to start and stop at specified intervals that sync up with robotics interactions or other processes.

Belt Conveyor Drives amp; Components Voith. To keep pace with the rate of advancement in mining, belts often need to be shortened or lengthened with relative ease. The Voith TurboBelt Storage Loop System enables changing the length of belt systems in a safe and productive manner. The conveyor belt is looped around 26 return pulleys with 13

Phoenix Conveyor Belt Systems is the global technology leader for the design and production of tailormade conveyor belt systems. Phoenix steel cord and textile conveyor belts operate in a reliable, economical, and environmentally friendly manner, in surface and underground mining.

support for your conveyor belts and systems worldwide. With highend conveyor belt technology from ContiTech, materials handling systems run reliably and cost effectively and are environ mentally friendly. As a leading development partner with innovative conveyor belt technologies, we support the mining,

Phoenix conveyor belt systems produces heavy weight conveyor belt for mining locations and a variety of industries around the expertise and experience has produced significant advancements in conveyor belt design, including world records for the strongest belt (both textile and steel cord), the steepest overland and worlds heaviest belt.

#0183;#32;The global conveyor belt market in the mining industry (henceforth, referred to as the market studied) was valued at USD 1,624. 2 million in 2019, and it is expected to reach USD 2010.

Conveyor systems have enhanced the way manufacturers move materials at each stage of production for well over a century. Primitive 19the century conveyor belts that moved massive coal and ore loads paved the way for todays whisperquiet, superefficient models.

To keep pace with the rate of advancement in mining, belts often need to be shortened or lengthened with relative ease. The Voith TurboBelt Storage Loop System enables changing the length of belt systems in a safe and productive manner. The conveyor belt is looped around 26 return pulleys with 13 pulleys mounted on a moving tensioning car.

Conveyor systems play an important role by minimizing the production cycle time. Earlier, limited conveyor belt types were available, but with the advancement of technology and change in demand, the conveyor systems market has drastically transformed. Automation has become an integral part of every industries for which conveyor systems are used.

phoenix conveyor belt systems mining technology. phoenix is the leading manufacturer of high quality conveyor belting for the worldwide mining industry. Get Price. the pamp;h mobile mining crusher (mmc), an advancement in in pit crusher conveyor (ipcc) system technology,

WhatsApp)

WhatsApp)