grinding pressure in vertical roller mill

Grinding trends in the cement industry. the vertical mill, the roller press (also known as highpressure grinding roll) and Each of the mill types and the associated grinding process are therefore more...

WhatsApp)

WhatsApp)

Grinding trends in the cement industry. the vertical mill, the roller press (also known as highpressure grinding roll) and Each of the mill types and the associated grinding process are therefore more...

01/04/2017#0183;#32;With the introduction of the high compression machines such as High Pressure Grinding Rolls (HPGR), Vertical Roller Mills (VRM) and Horomills, efficiency of the grinding circuits was improved in terms of energy and downstream effects. Among these devices, vertical roller mills have an important position in cement and mining industry. In literature, there are many studies performed in

11/02/2017#0183;#32;Vertical Roller Mill Training by PAI This video was made by PAI which introduce the working principle of Vertical Roller mills.

The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding. Within the cement industry, vertical roller mills are becoming more important as more cement producers look to increase their use of clinker substitute materials instead of importing clinker to meet localised rises in cement

The materials fall down the center of grinding table from feed opening. At the same time, hot air comes into the mill from the air inlet. Due to the centrifugal force, materials move to the edge of the grinding table. The materials are pulverized by the roller when by pass of the groove on the grinding table.

Grinding Pressure In Vertical Roller Mills. Grinding Pressure In Vertical Roller Mills The feeder a introduces raw material into the grinding chamber in the base of the roller mill b at a rate determined by pressure variations with the grinding mill plows located ead of each roller direct the material upward and between the grinding rolls,Grinding pressure in vertical roller price

vertical roller mill hydraulic system: component used for applying sufficient pressure to the grinding roller to crush materials. Controlled System. Pressure applied to the grinding roller being automatically controlled by the PLC/dCs enables the accurate control of grinding pressure and the highly efficient and stable operation of the mill without manual operation. Automatic control system

Cement grinding Vertical roller mills versus ball mills. The grinding process in ball mills and vertical roller mills differ fundamentally in a ball mill the comminution takes place by impact and attrition the comminution in the vertical roller mill takes place by exposing a bed of material to a pressure sufficiently high to cause fracture of the individual particles in the bed, although the

Five factors to increase the capacity of vertical roller mill. The grinding mill structure, scraper, hydraulic system, material and pressure difference of vertical roller mill will have an important impact on the capacity of mill. Here is a detailed analysis of it: 1) . Abrasion of internal structure of the mill: the parts that affect the capacity in the mill includes grinding roller, grinding

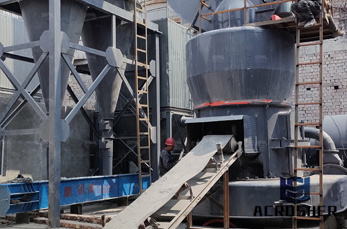

Vertical Roller Mill. Application of Vertical Roller Mill. Vertical roller mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etc.

Grinding pressure in vertical roller mill roller mill grinding speed is slow, so the vertical roller mill powder grinding capacity is other words, when the material contains relatively large amount of water, the material in the vertical mill machine will be prone to adhesion, but also very easy. Get Price. Prices / Quote. Vertical Cement Grinding Mill. Vertical Cement Grinding Mill produced by

The Application of Vertical Roller Grinding Equipment, Vertical Roller Mill Equipment: Vertical Roller Grinding Equipment, Vertical Roller Mill Equipment is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Mohss hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica

Grinding Pressure In Vertical Roller Mills. The feeder a introduces raw material into the grinding chamber in the base of the roller mill b at a rate determined by pressure variations with the grinding mill plows located ead of each roller direct the material upward and between the grinding rolls,Grinding pressure in vertical roller price. Grinding Pressure In Vertical Roller Mill

Up to six stationary grinding rollers roll on a rotating grinding table. The material is drawn in between the rollers and grinding table and ground by pressure and shear. The required pressure forces are produced by a lever system comprising, among others, a roller arm, along with a hydropneumatic tension system.

11/10/2019#0183;#32;The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a new entrant, is

The vertical roller mill is used to grind the material by using the principle of material bed pulverization. It gathers materials for grinding, conveying, powder selection, drying and separation of metal blocks and medium ore. Under normal conditions, the roller mill can run smoothly, increase production, reduce energy consumption, increase operating rate, and continuously improve economic

Vertical roller mills: The new leader in grinding technology. Oct 11, 2019 The two most common compressive comminution technologies are the high pressure grinding roller (HPGR) and the verticalrollermill (VRM). For now, the HPGR has already presented in a noteworthy number of mining projects whereas VRM technology, a get price

It is a misunderstanding that grinding aids for vertical roller mills (VRMs) should stabilise the material bed between the rollers and the table by adhesive forces between the particles. Grinding aids reduce the polarity of the cleaved surface and the attraction forces between particles. This means that agglomerates of fine particles and the packing of fine particles around a larger particle

WhatsApp)

WhatsApp)