DESIGN AND EVALUATE OF A SMALL HAMMER MILL

DESIGN AND EVALUATE OF A SMALL HAMMER MILL 484 difficulty of exact physical measurements like diameter, length, and thickness, may lead to errors in calculating stress, strain and modulus of

WhatsApp)

WhatsApp)

DESIGN AND EVALUATE OF A SMALL HAMMER MILL 484 difficulty of exact physical measurements like diameter, length, and thickness, may lead to errors in calculating stress, strain and modulus of

Next part in my series of building a hammer mill for processing grain to feed to my animals. Music by Talking Stain Dance by Audionautix is licensed under a

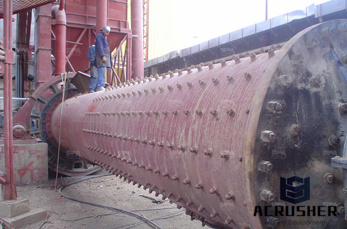

The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources . The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile. Further more, the hammer

design equation for hammer mills. optimal hammer design and placement will provide maximum contact with the feed ingredient. hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm 10 inches long, inches wide, and inches thick. Read More.

Small grain hammermills can be operated on current. Large hammer mills used in automobile shredders may be driven by diesel or electric motors ranging from 2000 to over 5000 horsepower ( ). The screenless hammer mill uses air flow to separate small particles from larger ones. It is designed to be more reliable, and is also

Hammer mill manufacturers are under increasing pressure to deliver mills of high productivity with a reduced level of vibrations. However, in practice, excessive wear of the rods carrying the hammers takes place, and cracks develop in the vicinity of the holes holding the rods with the hammers, with the possibility of breakaway fracture and disastrous consequences.

Jul 01, 2015#0183;#32;The hammer mill used in this study is manufactured by Fitzpatrick (Fig. 3(a)). The blades of the hammer mill pulverize particles along their rotational path. The shape of hammers is shown in Fig. 3(d). As shown in Fig. 1(b), the tips of the blades create a narrow region of intense shear near the surface of the screen. The screen size in this setup has less importance because the shearing is mostly being

Nov 02, 2017#0183;#32;There are many types of pulverizer mill coal pulverizer mill, hammer mill, ball tube mill, vertical spindle roller mill, bowl mill hammer mill used on farm for grinding grain and chaff for animal feed. It is also used as tires to crush coal, vertical spindle roller. This type of mill is found in utility plants and its uses tires to grind coal.

flow and size reduction in a hammer mill is thus critical to optimize the design and operation of such equipment. Milling experiments are performed using lactose non pareils in a laboratory scale Hammer Mill. The size and shape of the resultant progeny of particles are analyzed by sieves/light scattering and

Metallurgical ContentHammer Mill Reduction RatioHammer Mill ApplicationsHammer Mill Operating PrincipleHammer Mill CrusherHammer Mill Capacity TableHammer CrusherHammer Mill Crusher Capacity Table Operational Characteristics: The method of operation has a con#173;siderable effect upon the nature of the product. When minimum fines are a requirement, the hammer mill should always he

Jul 19, 2018#0183;#32;The detailed design procedure for a hammer mill machine is presented. The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screen.

Aug 02, 2019#0183;#32;This Hammer Mill / Mulcher will reduce your yard waste so you can turn it into burnable pellets for heat. This hammer mill works great! It costs about 200 to build! It''s stronger and better than a mulcher. It has a large capacity. You can use it to compost your yard debris.

Jan 11, 2016#0183;#32;Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a

158 Hammer Mill = ~30 pounds (1/2 bushel) of shell corn per minute. 198 Hammer Mill = ~60 pounds (1 bushel) of shell corn per minute. 420 Hammer Mill = ~150 pounds (2 #189; bushels) of shell corn per minute. Note: Raw material size entering the Hammer Mill depends on type of material.

DESIGN AND EVALUATE OF A SMALL HAMMER MILL. 484. difficulty of exact physical measurements lik e diameter, length, a nd thickness, may. lead to errors in

Optimal hammer design and placement will provide maximum contact with the feed ingredient. Hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, (~ inches) wide, and ( inches) thick.

hammer mill foliage, Model: TRF 400; ; 10 swinging hammers) was used for grinding of the palm kernel and groundnut shell. The mill was charged at a constant mass (m t) of 200 g for groundnut shell and 300 g for palm kernel shell. The mass of charge (m t)

Our hammer mill is a high efficiency grinder for size reduction in feed and food processing industries. Generally applied for dry materials with a bulk density of kg/dm#179;, it convinces through high production flexibility and minimal downtime.

WhatsApp)

WhatsApp)