Easy Homemade Ball Mill YouTube

DIY homemade ball mill. Easy to make Made from some PVC pipe, a few castors, and electric motor, and a power supply

WhatsApp)

WhatsApp)

DIY homemade ball mill. Easy to make Made from some PVC pipe, a few castors, and electric motor, and a power supply

offers 2,452 ceramic balls for ball mill products. About 29% of these are Ceramics. A wide variety of ceramic balls for ball mill options are available to you,

2,727 ball mill prices products are offered for sale by suppliers on, of which mine mill accounts for 26%, grinding equipment accounts for 5%, and ball screws accounts for 4%. A wide variety of ball mill prices options are available to you, There are 1,927 suppliers who sells ball mill prices on, mainly located in Asia.

#0183;#32;DIY homemade ball mill. Easy to make Made from some PVC pipe, a few castors, and electric motor, and a power supply

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles with quality workmanship and materials used in the construction of the component parts. Your Ball Mill reflects years of advancement in grinding principles, materials, and

Ball mills tumble iron or steel balls with the ore. The balls are initially 510 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. The action of other grinding

Dia 20mm150mm Grinding Media Forged Steel Ball Cast Iron Ball for Ball Mill Brief Description: Forged Balls Size: 20150mm Inspection: SGS/BV/TUV Origin:

Huanyu 1kg 304 Stainless Steel Grinding Balls for Lab Planetary Ball Mill (5mm) 69. 00. 10% coupon applied at checkout Save 10% with coupon. Get it as soon as Fri, Dec 18. FREE Shipping by Amazon. Arrives before Christmas Only 2 left in stock order soon.

ball mills have four grinding stations arranged on the quot;Sun Wheelquot; of the planetary ball mill. When the Sun Wheel rotates, the grinding balls inside the jars are subject to superimposed rotational movements, known as Coriolis Forces. The difference in speeds between the grinding balls and

For cleaning the balls in ball mill process, I''m doing ultrasonic cleaning with DI water, Acetone, and IPA (1 hour each) consequently. Whats the standard cleaning process? also the balls are Agate

#0183;#32;The number, size and mass of each ball size used depend on the mill load and whether the balls are being charged for the first time to commence an operation or as replacements for worn out balls. In determining the size of balls to be charged to commence a milling process, Coghill and De Vaney [10] indicated that the initial ball size was related to the maximum size of the feed.

Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel balls. An internal cascading effect reduces the material to a fine powder.

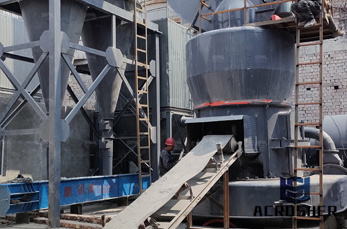

Short ball mills have a drum length less than drum diameter or equal to drum diameter. Long ball mills have a drum length more than one drum diameter, but less than three drum diameters. Pipe ball mills have a drum length longer than three drum diameters. Pic. 2. Cylindrical balls mill. A cylindrical ball mill used for grinding the coarse material.

Ceramic Ball Mill Repair. Aamp;B Industrial Ceramics is a South Carolina based supplier and installer of wear resistant ceramic linings and media in the ball mill industry. We own a complete line of equipment to handle small and large jobs in either the ceramic or refractory fields.

WhatsApp)

WhatsApp)