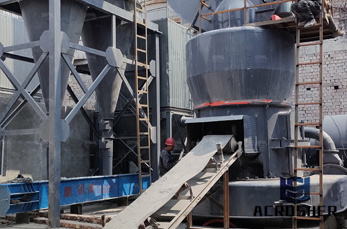

coal mill vertical shaft melbourne

WOA1 Know More. The extended portion of the vertical shaft coming out of the gearbox into the coalmill, is fitted with a bowl inside the mill.

WhatsApp)

WhatsApp)

WOA1 Know More. The extended portion of the vertical shaft coming out of the gearbox into the coalmill, is fitted with a bowl inside the mill.

vertical shaft engine Reference Materials vertical shaft engine

Why Vertical Shaft Wear Bowl Mill Rp 623. Milling Equipment: why vertical shaft wear bowl mill rp 623 A class of machinery and equipment that can be used to meet the production requirements of coarse grinding, fine grinding and super fine grinding in the field of industrial grinding. The finished product can be controlled freely from 0 to 3000 mesh.

Original Barmac#174; B Series vertical shaft impact (VSI) crushers Barmac#174; vertical shaft impact (VSI) crushers were the first vertical shaft impactors in the world. The original Barmac#174; VSI crusher was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globe.

Our range of Bowl Mill spares for various Combustion Engineering Designs include mill discharge valve assembly, multiple port outlet, bowl hub, roller journal assembly, upper amp; lower skirts. The raw materials used for these components are Nihard, SG iron, steel castings, castings amp; alloy steels.

Vertical Shafts. There are 4 methods in general use: Conventional drill, blast amp; remove stone (quot;muck outquot;) to surface with a winder. If the shaft is to be quot;linedquot; ( sides to be covered with a concrete or even a steel lining), this is normally placed as the shaft is excavated. Drill a pilot borehole from surface to existing underground workings,

Shaft Materials: A good practice for material selection: Start with an inexpensive, low or medium carbon steel for the first time through the design calculations. If strength considerations turn out to dominate over deflection, then a higher strength material should be tried, allowing the shaft sizes to be reduced until excess

13hp vertical shaft engine Reference Materials 13hp vertical shaft engine. Close #215; Shop Now. Pay Later. Interestfree.

3 m one piece shaft m one piece shaft m segmental shaft 6 m segmental shaft m segmental shaft 9 m segmental shaft m segmental shaft m segmental shaft 15 m segmental shaft Sizes up to 25 m are also available, please contact Humes for availability. 8 Tunnel and shaft solutions

22/3/2018#0183;#32;Vertical hammer mill: in this mill, the drive shaft is positioned vertically and screens and hammers are positioned horizontally. Material successfully reduced in size to the diameter of screen holes or smaller, are carried by gravity outside the mill and

A VSI mill (vertical shaft impactor mill) is a mill that comminutes particles of material into smaller (finer) particles by throwing them against a hard surface inside the mill (called the wear plate). Any hard or friable materials can be ground with low value of metal waste. This type of mill is combined with a classifier for fine tuning of a product size.

Bowl Mill is driven by AC motor, coupled with flexible coupling to the worm shaft. The worm shaft drives worm gear, mounted on the Main Vertical Shaft. A bowl mounted on the top of the shaft rotates at a speed of 40 to 65 rpm.

Where the shaft is to be used for hoisting it is frequently split into multiple compartments by Shaft Sets, these may be made of either timber or steel. Vertical members in a shaft set are called Guides, horizontal members are called Buntons. For steel shaft guides, the main two options are hollow structural sections and top hat sections . Top hat sections offer a number of advantages over hollow structural sections

Types. They are mainly classified into two types. Transmission shafts are used to transmit power between the source and the machine absorbing power; counter shafts and line shafts.; Machine shafts are the integral part of the machine itself; crankshaft.; Materials. The material used for ordinary shafts is mild high strength is required, an alloy steel such as nickel

A VSI mill ( vertical shaft impactor mill) is a mill that comminutes particles of material into smaller (finer) particles by throwing them against a hard surface inside the mill (called the wear plate). Any hard or friable materials can be ground with low value of metal waste.

Manufacturer of Bowl Mill Spares for XRP Mills Worm Shaft Thrust Bearing Housing, Oil Pump Hub amp; Bush, Gearbox Housing Cover and Bowl Mill Assembly

Vertical, radial and tangential stress components are usually developed around and along the shaft due to the 3D nature of the stress concentrations near a vertical circular shaft (Fig. 1a).

WhatsApp)

WhatsApp)