describe principle of grinding operation

describe principle of grinding operation There are three principle types of abrasive cutting tools according to the . From the principal abrasive operations, grinding is

WhatsApp)

WhatsApp)

describe principle of grinding operation There are three principle types of abrasive cutting tools according to the . From the principal abrasive operations, grinding is

6. It is capable of grinding many different types of materials. 7. The machine is easy to install and operate and its operation is continuous. 8. It occupies small space. 9. It is easy to maintain and clean. 10. It is inexpensive. 11. Its ease of manufacture allows easier local construction. Disadvantages of Hammer Mill

A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the m aterial. It is a process of metal cutting by using a rotating abrasive whee l from the surface of the workpiece. Generally, the grinding is finishing operation to show the high surface quality, accuracy of the shape and dimension.

describe principle of grinding operation. describe principle of grinding operation Grinding, Modelling and Ecoefficiency Springer connection arises due to the impact of the grinding process on the accuracy of other machining processes, such as milling, sections, chip formation, grinding process and grinding system are described in detail.

Read also: Ultrasonic Machining (USM): Parts, Working Principle, Advantages, Application and More. Accuracy: Because there is very little abrasive action, Electrochemical grinding does not leave fine scratches which may impair the finish and leave stress raisers. Tolerances of about + are held on rather complex grinding operations.

describe principle of grinding operation cylindrical grinding operation in chennai Cylindrical grinder Wikipedia,,Grinding mill machine, operation, wor

grinding machines perform the dressing task automatically. The application of coolants to the grinding process is important. Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life. Coolants are either emulsions, synthetic lubricants or special grinding oils.

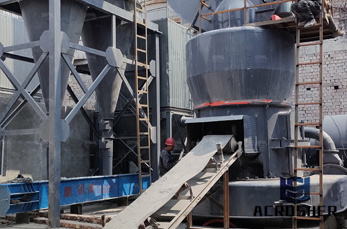

Grinding Mills Types, Working Principle lets take a quick look at the top manufacturers of Grinding drilling sets the stage for the next steps in the mineral processing operation.

W. Brian Rowe, in Principles of Modern Grinding Technology (Second Edition), 2014. Flexible Grinding Operations and Peel Grinding. Flexible grinding operation suggests that a family of components or possibly several families can be produced flexibly on one automatically controlled machine tool. For example, it is possible that cylindrical components having several diameters and shoulders could

Grinding Machine: Types, Parts, Working amp; Operations (With

describe principle of grinding operation palacehomes . describe principle of grinding operation. principles of operation of a grinding machine describe the operation of hammer mill . Chat now+ Surface grindingWikipedia. Chat Free

Read also: Ultrasonic Machining (USM): Parts, Working Principle, Advantages, Application and More. Accuracy: Because there is very little abrasive action, Electrochemical grinding does not leave fine scratches which may impair the finish and leave stress raisers. Tolerances of about + are held on rather complex grinding operations.

principles of centerless grinding. Sep 12, 2007 #183; Recognizing the unique design and nature of the centerless grinder, this class provides an indepth examination of how the centerless grinder itself and its components (grinding wheel and regulating wheel selection and profile) can effect the throughput and quality (part roundness, chatter, and surface finish) of the centerless grinder operation.

describe principle of grinding operation. Grinding mill machine, operation, working principle, parameter describe principle of grinding operation (Total: 10) 1524 Votes 3048 Comments . Explain The Construction Features And Operation Principles Of

Describe principle of grinding operation grinding mill equipment describe taper grinding operation mauritius 28 dec 2016 grinding meals for sale in zimbabwe ball mill . Get Price portable grinder operating procedures . portable grinder operating procedures does not include snagging or off hand grinding operations such as grinding the welds .

#0183;#32;Introduction Grinding is a metal cutting operation performed by means of abrasive particles rigidly mounted on a rotating wheel. Each of the abrasive particles act as a single point cutting tool and grinding wheel acts as a multipoint cutting tool. The grinding operation is used to finish the workpieces with extremely high quality of surface finish and accuracy of shape and dimension. Grinding

Grinding is the most common type of material cutting and surface generation process. Mostly grinding process is used to shape and to provide better finishing parts of metals. Grinding process uses one abrasive tool to make controlled contact with workpiece surface. Normally grinding wheel is used as abrasive tool in process of grinding.

#0183;#32;Types of grinding operation 1. Ruff or precision Grinding a) Snagging b) Offhand 2. Precision Grinding a) Surface grinding b) Cylindrical grinding c) Center less grinding d) Form and profile grinding e) Plunge cut grinding 5. Grinding Process Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. 6.

Grinding is a term used in modern manufacturing practices to describe machining with highspeed abrasive wheels, pads, and belts. Grinding wheels come in a wide variety of shapes, sizes, and types of abrasives. In recent decades, grinding has been evolved both for producing very high quality parts and for fast economic production.

WhatsApp)

WhatsApp)